HACCP Critical Control Points define the steps by which you can control or minimise hazards. The term “HACCP” represents a mandated standard for food businesses. The UK government follows Article 5 of Regulation (EC) No. 852/2004 from the EU Regulation to apply HACCP.

Authorities may take legal action for failure to comply with the HACCP regulations. In addition, non-compliance could lead to the closure of a food business. To build your HACCP system, you must develop clear and demonstrable Critical Control Points.

Table of Contents

What is HACCP?

HACCP means Hazard Analysis and Critical Control Points. It’s a method for controlling risks to food safety. Therefore, you should base your food safety management practices on HACCP.

HACCP focuses on biological, chemical, and physical hazards.

- First, identify the HACCP Critical Control Points.

- Next, assess the business areas with risk factors.

HACCP involves removing or reducing those factors to safe levels. In addition, it involves what action you need to take if something goes wrong.

HACCP Critical Control Points measure that you follow the right and effective procedures. It ensures that your systems are working. Also, it keeps records to prove your methods are effective. Meanwhile, you must enable suitable management practices to work on food safety in your business.

Why is HACCP Important?

HACCP is the only way to protect yourself and others from harmful consequences in food safety. With HACCP Critical Control Points, you can effectively recognise and reduce hazards.

HACCP makes sure of the following –

- foodborne infections and allergic responses don’t arise,

- poor hygiene doesn’t occur in food preparation facilities and processes,

- germs don’t multiply and enter bodies,

- you succeed in total elimination of bacteria,

- you are aware of the ingredients in the food,

- you avoid allergic responses in consumers,

- you stop mixing up ingredients or substances,

- and you provide proper labelling for food items.

Therefore, you must rely on HACCP. Each critical control point gives you insights into what is happening during the processing. In addition, it directs you to take necessary precautions.

What is a HACCP System?

A HACCP system controls food and pharmaceutical safety from the beginning of a procedure. The system covers producing and preparing food, including packing and distribution. Therefore, your inspections must cover any physical, chemical, or biological hazards from the start to the end of the whole process.

You can develop a HACCP system by following the HACCP principles and the HACCP plan. A HACCP plan is a written document that outlines the necessary protocols. Subsequently, you will have a structural HACCP system when implementing the HACCP Plan in your business. For example, you can use risk factors to identify food hazard likelihoods. In addition, you must utilise Critical Control Points (CCPs) to decrease or eliminate the risk of the hazards.

Hazard Analysis of Critical Control Points Principles

HACCP system offers the framework for monitoring the entire food system. It stays from production to consumption. You must use the system to spot and stop possible issues before they arise.

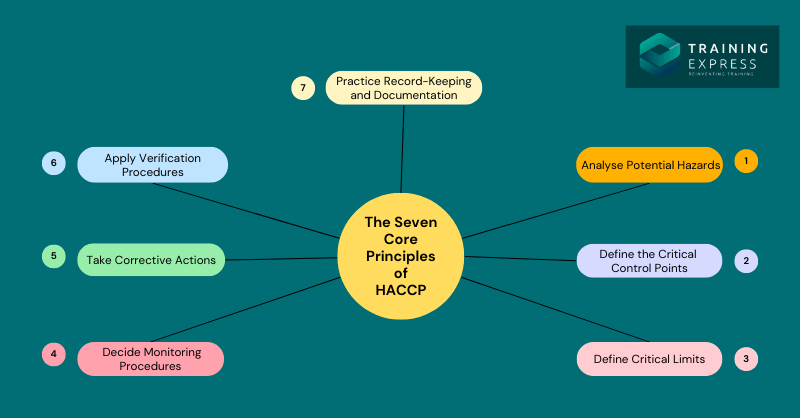

The Seven Core Principles of HACCP

The food industry, trade associations, and government organisations agree on the seven HACCP principles. The seven principles provide a helpful framework.

The seven core principles of HACCP are:

1. Analyse Potential Hazards

The hazard analysis aims to create a list of potential dangers. Hazard analysis is the process of collecting and evaluating information about various hazards associated with food. It also includes the decision about which hazards are significant and must be addressed in the HACCP plan.

2. Define the Critical Control Points (CCPs)

HACCP Critical Control Points may include

- thermal processing,

- chilling,

- checking chemical residue,

- formulation errors,

- and metal contamination.

3. Define Critical Limits

A critical limit is a maximum or minimum acceptable value at a CCP. Using the required limits to differentiate between safe and unsafe operating conditions would be best.

4. Decide Monitoring Procedures

Monitoring is a scheduled series of observations. Its purpose is to determine whether a CCP is under control and to create an accurate record. You can use it for verification in the future.

5. Take Corrective Actions

Less-than-ideal conditions can exist. These conditions may lead to process deviations. When deviations from established critical limits form, you must take corrective actions.

6. Apply Verification Procedures

Verification is the process of monitoring and establishing the accuracy of the HACCP plan. In addition, verification confirms that the system is working in accordance. The efficiency of a HACCP system depends on setting up appropriate verification methods. The verification methods may involve identifying

- the hazards,

- essential control points,

- and critical limits.

7. Practice Record-Keeping and Documentation

Record keeping and documentation may include

- a summary of the hazard analysis,

- the HACCP Plan,

- and support documentation such as validation records.

What is a Critical Control Point (CCP)?

A critical control point is an action you can control. It would be best if you used HACCP Critical Control Points to prevent, eliminate, or reduce risk to acceptable levels for food safety. When assessing CCPs, it is essential to consider any potential dangers likely to result in disease or harm in the absence of their control.

A critical control point location is any stage where you can avoid, eliminate, or lower dangers to acceptable levels. A few examples of CCPs can be

- thermal processing,

- chilling,

- checking for chemical residues in ingredients,

- containing product formulation errors,

- and limiting metal contamination.

Therefore, you must meticulously create and record CCPs. Additionally, you can utilise them for product safety objectives. For instance, a CCP could be a predetermined heat process at a set temperature and duration to eliminate a particular microbiological infection.

Similarly, CCPs could include freezing pre-cooked food to stop dangerous bacteria from growing. Also, it may be bringing a dish’s pH to the correct level to prevent toxins from forming.

HACCP Critical Control Points can vary between establishments preparing the same food items. For example, there can be variations in each facility’s

- design,

- furnishings,

- ingredient choices,

- operational procedures, etc.

How to Identify Critical Control Points?

You can’t just pick any value when determining a critical limit. You need a robust foundation and firmly established HACCP Critical Control Points.

First, pinpoint serious food safety risks and suitable CCPs. Next, carefully carry out the necessary preliminary actions to ensure that each limit is practical. Additionally, important limitations must possess the following qualities to be valid:

Observable

A food handler needs to observe any deviations to correct them. However, it could be more challenging, particularly during a busy manufacturing run. For this reason, a critical limit should be simple to determine quickly.

Monitorable

The production line will run in compliance with observable critical limits. However, for food handlers to instantly take corrective action, they must catch any deviation in real-time. The system should make it physically possible to let them do that.

Measurable

HACCP Critical Control Points limits must be quantifiable using the proper techniques. For example, the limits could be

- acidity level titration,

- microbiological testing,

- chemical testing,

- visual examination,

- and other analytical testing procedures.

You will compare the results of these tests to the accepted criteria to assess whether a food product is safe for consumption. Each CCP might use numerous HACCP critical limits. Therefore, you must ensure that each limit is precisely measurable before proceeding.

What are the 8 HACCP Critical Control Points?

The Critical Control Points can change depending on the business. However, you can use the following eight HACCP Critical Control Points to run your HACCP system.

1. Sourcing Food

It provides specific information about food sources and the kinds of items bought. Examples of HACCP Critical Control Points when sourcing food include the followings.

- Verify suppliers’ food production, sourcing, and traceability.

- Examine their capacity to uphold respectable HACCP procedures.

- Prepare labelling, storage, and temperature control procedures for packaged and frozen items.

2. Delivering and Receiving

It refers to how you handle coordinating food deliveries. HACCP Critical Control Points when delivering and receiving food indicate the followings.

- Temperature control provides information about safe temperatures.

- Verify deliveries before signing the delivery receipt.

- To regulate food temperatures, transfer to storage as soon as possible.

3. Storage of Food

This step ensures that you store food correctly and per the manufacturer’s guidelines. In addition, these HACCP Critical Control Points guarantee avoiding cross-contamination, allergens, and disruptive temperature. HACCP Critical Control Points at food storage involve the followings.

- Keep containers organised, covered, date-stamped, and lightweight.

- You should store food on shelves.

- The storage facilities should have adequate walls, floor clearance, and pest control.

- It would be best to segment hot, cold, and dry storage.

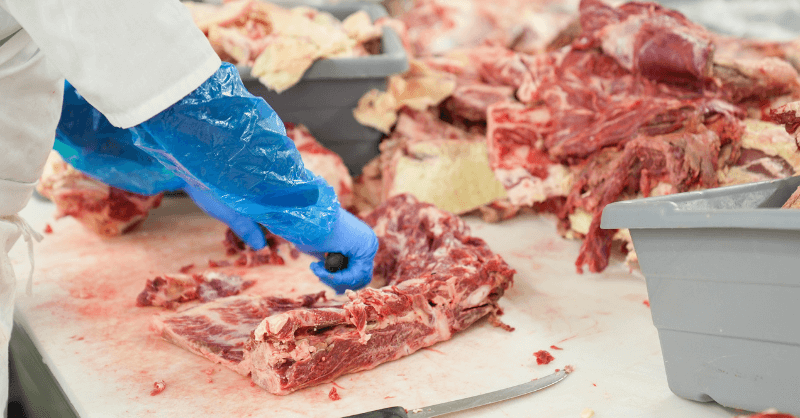

4. Preparation of Food

This step focuses on how you handle and prepare food. HACCP Critical Control Points in the preparation of food include the followings.

- You must be aware of cross-contamination. For example, avoid preparing meats, raw and prepared foods, and allergen-containing foods in the same space.

- Food separation is only one aspect of allergen management. Therefore, you must implement additional measures.

Again, it would help if you describe the following, especially concerning temperatures, checks, and equipment.

- cooking.

- reheating.

- and thawing processes.

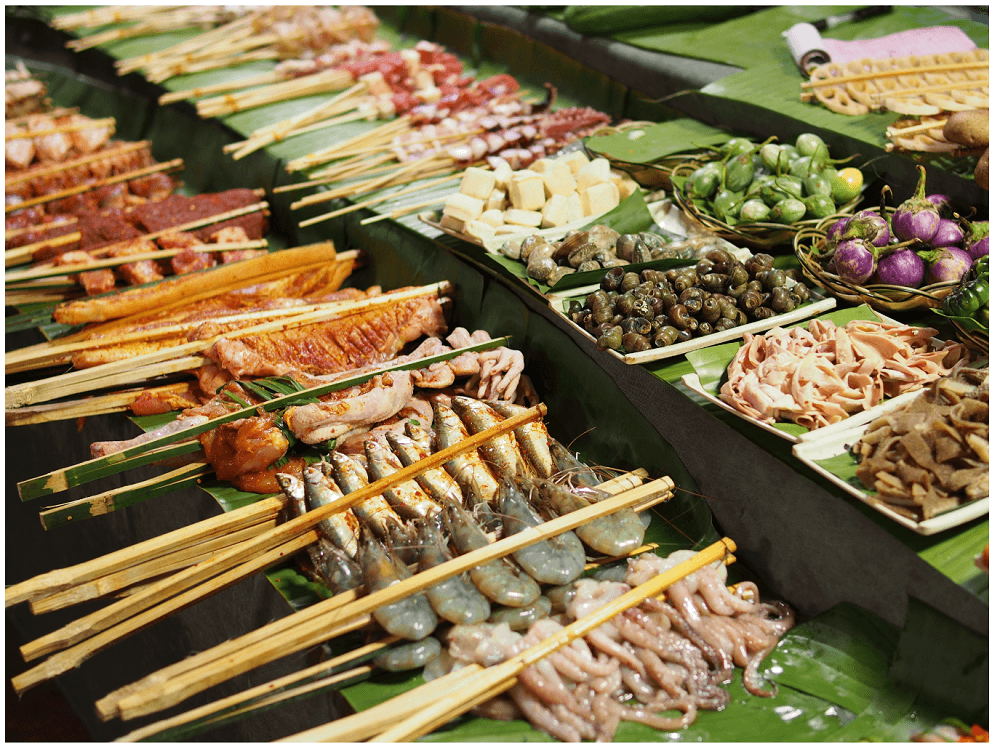

5. Service or Display of Food

Following are some instances of HACCP Critical Control Points management for managing the serving of your meals and any display areas:

- To protect food on display, you should offer suitable, hygienic facilities.

- Your food safety document should go into depth about the criteria for hot, cold, and frozen collections.

- Target both self-service and full-service.

- Ensure proper training, labelling, and allergen equipment management.

6. Maintaining and Cleaning

This step considers the cleanliness of your kitchen, storage rooms, overall facility, and the cleaning agents and tools you employ. Pest management and garbage management are also parts of it.

HACCP Critical Control Points in maintenance and cleaning include the followings.

- Use Standard Cleaning Process to ensure the hygiene of the premises and the food preparation spaces.

- Follow COSHH procedures and conduct Risk Assessment.

- Keep all cleaning supplies and equipment away from food.

- Do not pour food down the drains.

- Properly dispose of wasted oils.

- Make sure the management of pest control follows specific protocols.

7. Personal Standards, Staff Training, and Hygiene

It considers staff competency to handle food safely and hygienically. In addition, it includes food safety training and hygiene awareness. Examples of HACCP Critical Control Points management for personal standards, staff training, and hygiene may involve the following things.

- Protect cuts and wash your hands thoroughly with hot water and soap.

- Your gloves should be replaced frequently. However, it shouldn’t stop you from cleaning your hands. In addition, staff who handles food must report illnesses.

- Wear spick-and-span attire or aprons that are suitable for the occasion.

- Net your hair and keep it away from food.

- Qualified instructors must give training at the appropriate level.

- Observe and review records.

8. Inspection and Diagnostics

This step ensures you carry out and document all necessary inspections at a CCP. HACCP Critical Control Points in inspection and diagnostics include the followings.

- Equipment used for testing must be calibrated, compliant with national requirements, and kept in a particular operating state.

- The management evaluates documents and carries out daily inspections.

Other CCPs in the Food Industry

Suppose your hazard analysis shows that a food hazard is likely to exist in your dairy product. In that case, you may need to implement other HACCP Critical Control Points measures. In every food processing, the other CCPs may involve the followings.

Thermal Processing

Thermal cooking techniques don’t always become HACCP Critical Control Points. Such as, you thermally process the dough to bake it into bread. However, you don’t use thermal processing to eliminate bacteria here. The nature of your food business would determine whether you would consider thermal process steps as HACCP Critical Control Points.

Thermal processing CCP destroys microbiological pathogens contaminating products or existing naturally in them. Remember, you must maintain the nutritional quality while thermally processing an item.

An excellent example of thermal processing CCP is cooking meat to the desired temperature. Ideal temperatures for cooking meats like chicken, beef, or pork practically apply to every business. For example, the thermal cooking CCP for chicken is cooking the poultry meat to at least 165°F.

Low-temperature or cold storage is an example of HACCP Critical Control Points. You may use cold storage to limit the growth of microbiological pathogens. In addition, cold storages halt enzymatic degradation. Enzyme processes, including the following, come to a complete halt at low temperatures.

- protein breakdown,

- oxidation,

- and browning.

Temperature-Intensive Storage (Hot Holding)

You should follow the 2-hour / 4-hour rule for any hot meal that requires high-temperature holding, such as

- soups in cafeterias

- or food items in a buffet setup.

Anywhere between 5°C and 60°C is considered a danger zone for temperature. This is because most germs thrive best in this range. Therefore, you must keep foods at higher temperatures. Then, you may proceed to serve them at room temperature.

You should not keep the following food in the danger zone.

- Rice and pasta,

- cooked vegetables,

- some fruits,

- meat, and foods containing meat,

- dairy, and similar goods,

- as well as egg products.

You must use or ingest the food within 4 hours (ideally within 2 hours). Moreover, you must not consume foods after this specified time and must throw them away immediately.

Food Processing

HACCP Critical Control Points occur when you use natural and synthetic preservatives. For example, the addition of an acidulant, such as the following, is a CCP.

- vinegar,

- lactic acid,

- or citric acid.

Acidulants stop the growth of microbial pathogens like Staphylococcus aureus in prepared meals and Clostridium botulinum in canned foods. Similarly, you must immerse specified vegetables in brine solutions before acidifying them. It lowers water activity and eliminates present pathogenic microbes.

You can give additives in food to help them last as long as they are supposed to. However, when the quality of these additives is in question, they may endanger consumer health and the safety of processed foods.

For example, you make juices in PET bottles. Most juices are naturally acidic. As a result, they will stop the growth of bacteria. However, they will not prevent mould growth. Therefore, you must prewash PET bottles with sodium benzoate to address this potential risk.

You must inspect food packaging materials to ensure quality supply. Due to chemical concerns, some packing materials may not be appropriate for your items. For example, look into the canning of acidic foods. When you utilise the wrong kind of cans, the extremely low pH of acidic food can lead to corrosion.

Another example of HACCP Critical Control Points is the assurance of clean facilities. Chemicals from the food processing machinery and environmental contaminants can affect packaging materials.

Testing for Physical Hazards

The ingredients you acquire during the raw material receiving process must be free of significant contaminations. For example, you may use metal detectors as a CCP in large quantities of food. However, this method would only work with metal items. Additionally, not everyone can afford to buy such equipment.

You may detect hair, insect and rodent bits, mirror shards, and other physical contaminants. Pre-inspecting raw materials before usage is a CCP in smaller-scale food production processes.

Testing for Chemical Hazards

Chemical dangers frequently found in hazard analyses include

- substances for sanitising and cleaning equipment,

- residues from animal drugs,

- and excessive amounts of food-grade vitamins.

Depending on the business and its protocols, each hazard has a different chance of happening. For example, cleaning and sanitising chemicals must have established HACCP Critical Control Points. The critical limits for each Cleaning in Place (CIP) system regulated the concentration of the cleaning and sanitising chemicals.

A CCP at the raw milk receiving facility can be animal drug residues. In this case, the critical limit is the absence of any detectable animal drug residue. Moreover, a CCP is mandatory in handling food-grade vitamins at the point of injection or addition into the milk stream.

Storage and Transportation

People frequently overlook this CCP example of storage and transportation. Raw materials are vulnerable to deterioration during storage and transportation, including

- punctures,

- cross-contamination,

- rodent bites,

- and other problems.

Seafood Hazards (Scombrotoxin)

You must identify HACCP Critical Control Points while processing seafood. For instance, food poisoning from scombrotoxin-contaminated seafood is a global problem. Therefore, to prevent the production of scombrotoxin at the receiving end, you must develop a CCP.Allergenic Hazards

You can put allergen in a different category rather than putting it in the category of chemical dangers. It’ll make allergen detection easier. Every food has the potential to induce an allergic reaction. However, some allergens are more likely to do so. The Food Standards Agency (FSA) has listed 14 significant allergens. In the UK, Natasha’s Law mandates that food businesses adequately disclose all known allergies on product packaging. The law went into effect on October 1st, 2021.Why Do We Need to Identify CCPs?

HACCP Critical Control Points give you the specific points you need to set limits to. Maintaining the critical limits ensures the safety of your served or sold food. Therefore, you should be able to identify CCPs effectively.

Avoid Food Hazards

Your food operation must have specific HACCP Critical Control Points to avoid contamination or deterioration of food.

For example, the importance of thermal processes is mentioned earlier. If you don’t identify that an exact time-temperature boundary is necessary to destroy pathogens, you’ll be unable to provide safe food. In addition, different foods require different levels of thermal processing. The CCP defines the temperature and the processing period of the meal.

Similarly, you can look into the pasteurisation process of milk. Pasteurisation prevents enteric infections. It inhibits Mycobacterium tuberculosis from contaminating healthy foods like milk.

The initial safe limit is 63°C for 30 minutes when pasteurising milk. You must choose this time-temperature combination to destroy the bacteria. Then, raise the temperature to 71°C for at least six seconds shortly after establishing the previous limit to tackle the biological threat Coxiella burnetii.

Such pathogens cause foodborne diseases if you lack the proper knowledge of HACCP Critical Control Points and their defined critical limits. Moreover, it’ll affect your consumer health condition. As a result, complications can arise in your food business. Also, you may face legal consequences.

Hygiene CCPs

Another thing is you establish hygiene conditions in a food facility. To do this, you must identify HACCP Critical Control Points. For example, discover hygienic design concepts that aim to stop the spread of pathogens. You may define the minimum and maximum contact times and the frequency of the chemical cleaning solution as critical limits in this area.

Some organisations suggest that you should clean food contact surfaces every 4 hours. However, more than four hours without cleaning the surfaces can encourage the growth of infections. Now, you may consider this fact to identify your HACCP Critical Control Points.

Again, studies on chemical sanitisers have revealed that you shouldn’t use them for shorter periods than recommended. If you do, they become insufficient to eliminate pathogens from surfaces. In addition, they become unable to maintain hygienic conditions. Therefore, it would help if you identified the CCP and its critical limit correctly.

Digital Solution to Identifying Critical Control Points

A successful HACCP implementation needs

- correct hazard identification,

- determining your critical limits,

- and implementing the appropriate monitoring methods.

Hence, you must establish CCPs and critical limits on a thorough evaluation and truthful reports. In addition, it helps create an extensive HACCP food safety management plan. At first, you must set critical limits. Next, you will make the necessary adjustments for thorough verification processes.

HACCP software makes

- fast,

- precise,

- and automatic setting of critical limits.

In addition, your food business may need a food safety consultant for impartial advice and assistance in developing HACCP plans. Despite this, employing a food safety expert is not inexpensive. Therefore, a digital HACCP solution is required to make plan-making for the HACCP food safety programs easier.

An entire digital HACCP entails the followings.

- A simple block-style flow chart of your daily operations.

- Accurate hazard analysis and hazard identification.

- CCPs for each significant risk.

- Precise and scientific critical limits for each CCP.

- Digital CCP monitoring forms.

- Appropriate procedures for any monitoring technique.

- Corrective measures in the event of limit violations.

- Finalisation of the verification phase.

- Standardised documentation and record-keeping practices.

A digital HACCP plan is a step toward a more sustainable food chain. However, a complete system shouldn’t entirely depend on digital strategies alone. It would be best if you combined both the conventional and the digital to utilise the best of both.

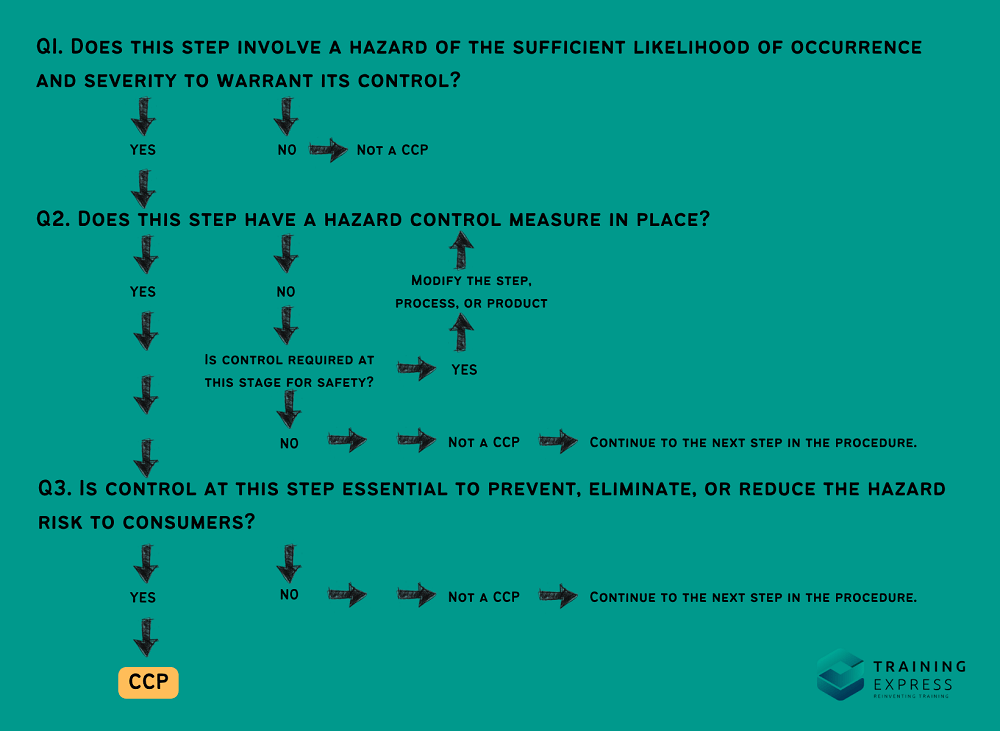

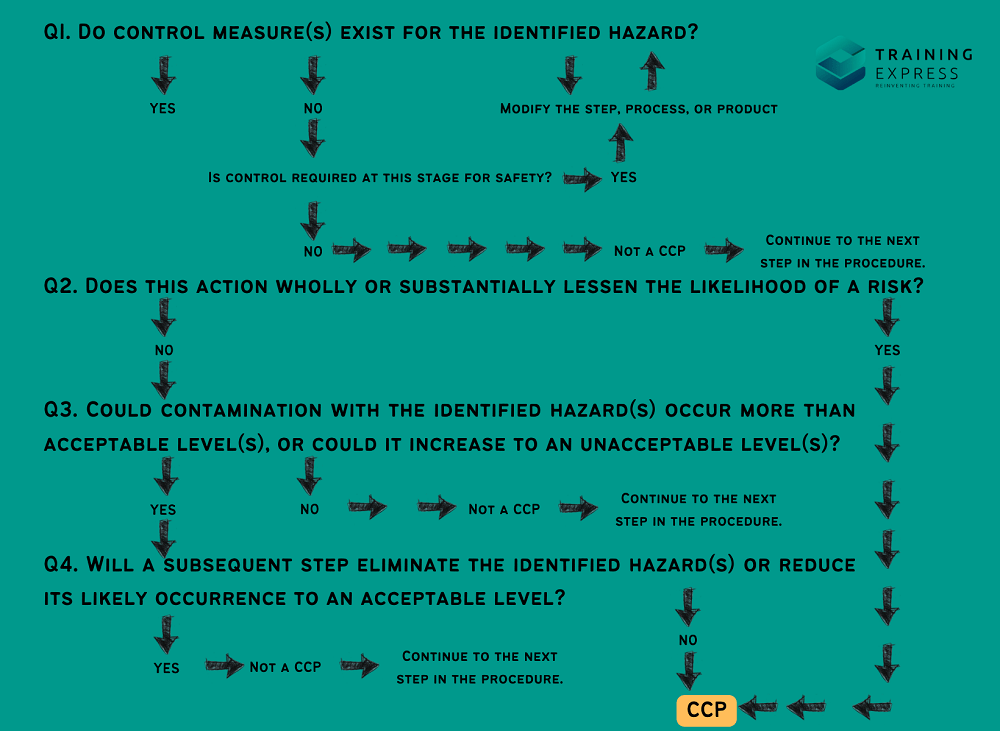

Critical Control Point Decision Trees

When you utilise the decision tree, keep some essential things in mind.

- After doing the hazard analysis, you can apply the decision tree.

- When identifying a hazard, apply the decision tree at those steps.

- The desired CCP may be at a later stage in the process.

- Controlling a danger may entail more than one process stage.

- You may use a particular control measure to manage many hazards.

The following figures, a and b, describe two different decision trees to identify CCPs.

Figure A: Decision tree to determine the CCP.

Figure B: Another type of decision tree to determine the CCP.

What are Control Measures?

Any action or activity utilised to prevent, remove, or reduce risk to acceptable levels for food safety is a control measure.

The food safety management standards call for effective control measures for food hazards. It ensures that food is safe for human consumption. You must also choose and categorise control measures based on their impact on known food safety issues. When classifying control measures in Food Safety Management Systems (FSMS), you can use the COntrol MEasures CATegorization (COMECAT) method. It helps businesses focus their limited resources and efforts on reducing essential hazards. Moreover, the technique allows them to stay true to the requirements of ISO 22000:2005.

To appropriately tackle a hazard, you may require more than one control measure. For example, all of the following are necessary to prevent the risk of metal fragments in food.

- You utilise a metal detection system.

- You maintain the detection equipment.

- You receive training on how to use it.

On the contrary, a single control measure may control multiple hazards. For example, maintaining the oil temperature and frying time can effectively lower the levels of Salmonella and Campylobacter in fried food.

You may not always need to implement a control measure in a hazard-occurring step. You can implement the control measure before or after the stage.

What are the Differences Between CP, CCP, PRP, and OPRP?

Terms such as control points, prerequisite programs, or operational prerequisites programs may appear in a HACCP food safety plan. To differentiate among the four key phrases, let us look at the following table:

| Control Measure | Control Point (CP) | Critical Control Point (CCP) | Prerequisite Program (PRP) | Operational Prerequisite Program (OPRP) |

| Monitoring | CAN be monitored | MUST be monitored | CAN be monitored | CAN be monitored |

| Core Aim | Understanding risks in food safety | Eliminating or limiting risks in food safety | Providing clean and hygienic conditions | Limiting risks in food safety |

| Intended Application | General to the whole processing | Particular to each process | General for the entire processing | Particular to each process |

| Grounds of Establishment | Identifying steps dealing with hazards | Assessment of hazards and risks | Knowledge of food safety | Evaluation of hazards and risks |

| Analytical Standards | Verification | Critical Limits | Verification | Detection |

| Consequence of Noncompliance | No health risks | Unsafe food & legal action | Not unsafe food | Not unsafe food |

FAQs

When is the Best Time to Monitor Critical Control Points?

Continuous monitoring is preferable to discontinuous ones. If it’s impossible to monitor continuously, establish a monitoring frequency for a CCP. You must use data-gathering or sampling systems. Statistically, samplings are well suited for this. You will know the exact times and places to establish a monitoring system from past hazard histories. Most monitoring procedures need real-time activities. Thus, prolonged analytical testing is not usually possible.

If you recognise a loss of control at any CCP, you must bring adjustments as soon as possible. Additionally, you must report a method or product immediately if it doesn’t adhere to its standards.

What are the Observations at Critical Control Points Called?

Monitoring is the term used to describe the observations at Critical Control Points or CCPs.

What is the Purpose of Conducting a Hazard Analysis and Determining Critical Control Points?

The purpose of conducting hazard analyses and determining CCPs includes the following.

1. Limit timeframes and temperatures in the recipes and procedures.

2. Monitor the food temperature while your staff prepares, holds, cooks, and cools it.

3. Adjust the temperatures if the required temperatures are not being met.

4. Review the whole process, and examine deviations and adjustments.

5. Visually inspect the food hazards.

6. Examine recipes that may contain harmful or allergenic substances.

7. Flag hazardous food or food processes.

Take a look at our HACCP (Hazard Analysis and Critical Control Points) accreditation and training course and enhance your food safety knowledge.

Summary

To sum up, food safety necessitates a well-established HACCP. On top of that, eight HACCP Critical Control Points are the core CCPs of a HACCP system. It would be best if you used these CCPs to avoid hazards like cross-contamination, allergens, and disruptive temperatures. However, you must maintain nutritional quality while applying a disinfection process.

The nature of your food business would determine which steps you will consider critical control points. In addition, you may use decision trees to assess the CCPs. Also, don’t forget to establish critical limits in each CCP. It would help if you also kept in mind that HACCP doesn’t focus on after-inspections in processed food.

HACCP is a system that prevents or minimises hazards before the final product is delivered. If you haven’t done so, you must set up the HACCP system in your food business with Level 3 HACCP Training.

- Available Courses

- Law10

- IT & Software225

- Design28

- Training6

- Accounting & Finance Primary48

- Teaching & Academics Primary36

- Teaching22

- Quality Licence Scheme Endorsed160

- Healthcare169

- Animal care10

- Job Ready Programme52

- Charity & Non-Profit Courses28

- HR & Leadership4

- Administration & Office Skills2

- Mandatory Training36

- Regulated Courses4

- Health and Safety520

- Marketing38

- Career Bundles201

- Construction59

- Electronics31

- Hospitality28

- Health and Social Care289

- Child Psychology40

- Management423

- Business Skills292

- First Aid73

- Employability283

- Safeguarding79

- Food Hygiene116

- Personal Development1597

Food Hygiene

Food Hygiene Health & Safety

Health & Safety Safeguarding

Safeguarding First Aid

First Aid Business Skills

Business Skills Personal Development

Personal Development